Top 10 Tips To Assess The Regulatory Compliance Of PAT in Coventry

The regulatory landscape for Portable Appliance Testing (PAT) in the UK is fundamentally different from the prescriptive requirements governing fixed electrical installations or fire safety equipment. Unlike the fire extinguisher testing that is subject to British Standards and third party certification schemes, the PAT test is governed under a health and safety framework which emphasizes duty of care and risk assessment rather than mandatory schedules for periodic testing. Electricity at Work Regulations (1989) state that electrical systems, including portable equipment, must be regularly maintained to avoid harm. The Regulations are silent on how this should be done, nor do the regulations specify a testing schedule or methodology. In this case, it is up to the dutyholder to perform a thorough and adequate risk assessment and determine an appropriate inspection and maintenance regime. Compliance is not demonstrated solely by a pile of test results, but rather by a system of risk-based assessment, competent implementation, thorough documentation, and a documented process that demonstrates a systematic approach in ensuring electrical safety on the job.

1. Electricity at Work Regulations, 1989: The Legal Basis

Regulation 4(2) of 1989's Electricity at Work Regulations is a cornerstone to PAT test compliance. This regulation states that "As it may be necessary to avoid danger, all system shall be maintained in order to prevent, to the extent reasonably practicable, any such danger." The regulation imposes a duty of care on employers and their duty holders. The term system includes portable appliances. Importantly, the regulations do NOT mention "PAT Testing"; they mandate "Maintenance," an encompassing concept which includes visual inspections, user checks, combined inspection and testing, as well as a wider concept of maintenance. The frequency and type of maintenance required are determined by the risk assessment, not by a fixed legal timetable.

2. The Health and Safety at Work Act, 1974 Act 1974

The Health and Safety at Work (etc.) Act 1974 is the overarching legislation which establishes the general duties employers have towards employees and others. The Health and Safety at Work Act 1974 establishes general obligations employers have to employees and others. According to Section 2 of this Act, employers must ensure that all employees are safe and healthy, in the best way possible. Electrical equipment is included in the safe operation of electrical systems and plant. Section 3 extends the duty to individuals who are not employed by them, such as contractors, visitors, and members from the public. The PAT test process is one of the most effective ways to meet these duties. It provides a systematic approach for ensuring electrical safety.

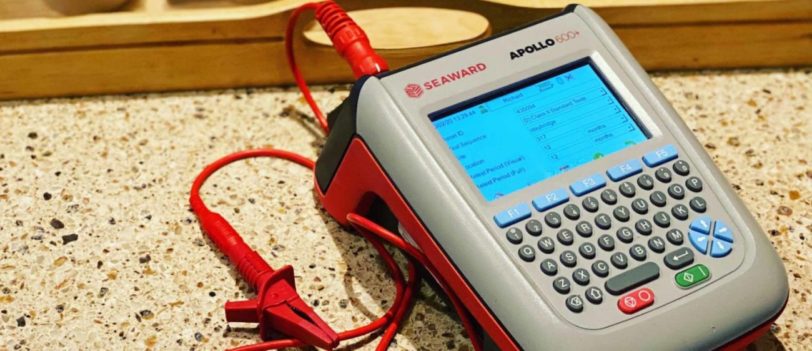

3. Guidance and Best Practice: The IET Code of Practice for In-Service Inspection and Testing of Electrical Equipment

Although not law, the Institution of Engineering and Technology Code of Practice (IET Code of Practice) is universally recognized as the benchmark of best practice for PAT tests. It contains detailed information on how you can implement a compliance maintenance regime.

Definitions of appliance categories and types.

Procedures for inspection and testing combined with formal visual inspections.

Initial recommended frequency for inspections and tests based on the equipment type and operating conditions.

Results of tests are graded on a pass/fail basis.

Courts and Health and Safety Executive Inspectors (HSE), who will judge whether the maintenance regime of a dutyholder is "suitable and enough," will use this standard. Deviation from the code without a robust, documented risk-based reason can be seen as a failure to comply with the overarching regulations.

4. Risk Assessment is the Priority

HSE is clear in its support of a risk based approach to PAT tests, as opposed to the outdated notion of testing all equipment annually. A risk assessment must be carried out by the dutyholder to determine if inspections and tests are necessary. A number of factors will influence the assessment.

Equipment type: A double-insulated (Class II) appliance in a low-risk environment may only need a visual check, while a Class I appliance in a workshop may need regular formal testing.

Environment: Construction sites and warehouses are high-risk environments. Hotels and offices pose a lower level of risk.

Users: Are the equipment users members of staff or public?

What is the history of your appliance? Is it new or has it been frequently damaged in the past?

The risk assessment of a system determines its compliance, and not the quantity of tests.

5. The Testers' Concept of "Competence

Regulation 16 of the Electricity at Work Regulations 1989 requires that persons engaged in work on electrical systems must possess the necessary technical knowledge and experience to avoid danger. In PAT tests, "competence", does not always require formal qualification. However, the tester must possess:

Electricity is a subject that requires adequate knowledge.

The ability to work with the system in question and have an understanding of it.

Understanding the hazards to be aware of and what precautions are needed.

Ability to correctly interpret and use test results.

City & Guilds' 2377 qualification is a very popular qualification, and it provides an excellent education. But competence can also be attained through other means. The duty holder must be able show that the person who conducts the testing is competent.

6. Documentation and record-keeping requirements

The Electricity at Work Regulations do not explicitly require record-keeping. Regulation 29 however states that proving due diligence and taking all reasonable steps in order to avoid committing the offense is a defence. Primary evidence of due care is comprehensive records. A compliant record-keeping system should include:

The asset register is a list of all equipment.

A record of the risk assessment and the resulting maintenance plan.

Detailed reports are provided for each formal test and inspection, which include the following: appliance description and details, test results and pass/fail grades, next scheduled test date and tester identification.

HSE officials or local authorities should be able to easily inspect these records.

7. Appliance Labelling and Identification

Effective labelling plays a crucial role in a compliant PAT. Each appliance which has undergone an official combined inspection/test should be labelled:

A unique asset ID number that ties it to the record.

The test date.

Date for next test (or inspection).

The name, or identifier, of the tester.

The label is a visible indicator that shows users and inspectors the compliance status of an appliance. Labels need to be durable, not metallic, and not conductive.

8. The HSE Enforcement position and "Myth Busting"

The HSE is actively working to dispel misconceptions surrounding PAT tests. They stress that:

The annual testing of all equipment is not a legal requirement.

There is no legal requirement that businesses use third-party contractors if their staff are competent.

Visual inspection is more important than electronics testing, and can detect the majority faults.

A law enforcement officer will be looking for a risk based approach. A company testing equipment without risk assessment every year may be looked down upon by enforcement officers.

9. PUWER: 1998 – Interaction with other Legislation

The Provision and Use of Work Equipment Regulations (PUWER), which was passed in 1998, also apply to portable appliances. PUWER requires that work equipment be suitable for its intended use, maintained in a safe state, and inspected to ensure it remains safe. Regulation 6 specifically requires inspections where safety is dependent on installation conditions. The PUWER inspection and maintenance regulations for electrical work equipment are met by PAT testing, which is a critical method.

10. Insurance and Due Diligence

While insurance companies have certain requirements, the law bases its assessment on risk. A policy may stipulate that PAT testing is conducted annually by a third party as a condition of coverage. Unable to comply with this requirement could invalidate your claim. Insurance companies and HSE will also scrutinize the dutyholder’s risk assessment and PAT testing records in the event that an electrical incident occurs. The best evidence for due diligence is a well-documented and risk-based management system. This will also provide a strong defense against prosecutions or invalidated insurance claims. See the most popular Coventry electrical equipment testing for blog examples.

The Top 10 Tips To Support Emergency Services Fire Extinguisher Services in Coventry

Support for emergency fire extinguisher maintenance is the frontline of your compliance with fire safety, in which theoretical procedures meet demands. The Regulatory Reform Order (Fire Safety) 2005 states that the Responsible Person is responsible for maintaining firefighting equipment at a high performance. Equipment failures or damage and the discharge of it result in a gap in compliance that should be rectified immediately. The emergency support services aren't just a convenience, but are an integral part of a comprehensive strategy for fire safety which directly impacts the management of risk, insurance validity and operational continuity. A provider's emergency response capability–encompassing availability, communication, technician competence, and logistical readiness–reveals their true commitment to client safety beyond routine maintenance. To analyze these clauses it is important to review the service level agreements, geographic coverage restrictions, as well as the actual application of responses promised in real-world situations.

1. 24/7/365 Access and Special Emergency Contact Channels in Coventry

To provide genuine emergency assistance 24/7 availability is necessary. This means that an emergency number is accessible all hours of the day and 365 days a year. It should not be a standard number that connects directly to voicemail, but it should be a hotline with a person on the line who can send engineers away. It is crucial that the service provider has clear procedures to handle calls during off hours. Otherwise, an emergency that is reported won't be handled until the next working day.

2. Clearly Defined and Contractual Reaction Time Guarantees in Coventry

The vague promises that a "rapid response" is promised is useless without any contractual guarantees. Your Service Level Agreement (SLA) must include the specific and measurable tiers of responses. For instance Priority 1 (Critical malfunction which affects multiple units): Engineer dispatched with 4 hours. Priority 2, (Single Unit Missing/Discharged) Site Attendance within 24 Hours. These tiers are clearly identified in terms of the risk. The SLA should also specify the consequences for repeatedly failing to meet the targets. This makes a promise an enforceable standard.

3. Geographic Coverage and Local Engineer Deployment

Geographic logistics is the only way to ensure quick response. National service providers needs to have an engineer network strategically located to provide local coverage. Inquiring about the availability of the engineer for your specific area is essential. If the company has engineers located within your city or area and they are able to meet a 4-hour deadline. If, however, the engineer needs to be dispatched from another Coventry, this is not possible. Understanding their deployment models is vital to assess whether the promises they make regarding their response are real.

4. Emergency Services: Assessments, Repairs, and Replacement in Coventry

The emergency response needs to be comprehensive. The scope of services must include immediate assessment on the spot, and the capability to repair using the stock available (seals hoses pressure cartridges) and replacing condemned extinguishers or ones that cannot be repaired by a van that has an adequate supply. A response consisting only of an engineer visiting to condemn a unit before leaving, and then requiring a second visit days later to put in a new one, is not sufficient. This leaves the asset vulnerable and the building in non-compliance for a long period of time. True emergency assistance resolves problems in the first visit.

5. Equipment Loaned During Resolution Period in Coventry

A premium emergency service will lend equipment for more complex problems that cannot be resolved immediately (e.g. specialist equipment that requires ordering). This is a method to ensure that your fire safety cover is in good working order during the entire resolution process, showing a provider’s dedication to your respect. What are the conditions? Is there a charges? How long is the loan duration? How will the loaned items be tracked and managed by you? This service is even more essential in areas with a lot of risk, like those in which leaving the fire-proofing points empty isn't a viable option.

6. Communication Protocols and Proactive Updates in Coventry

In times of emergency situation, clarity in communication is vital. The procedure of the service company should include a telephone acknowledgment, an estimated time for arrival (ETA), and notification of the engineer's arrival. A complete emergency service report should be prepared immediately following the visit. It should include the issue, any action taken and the replacement of components. The report is a vital proof for your insurance records as well as the compliance documentation.

7. Price transparency in emergency callouts in Coventry

To avoid disputes to avoid disputes, emergency pricing needs to be transparent. The contract or price list must clearly outline the cost of an emergency call-out, including any additional charges for nights weekend, weekdays, or bank holidays. It should clearly distinguish between the call-out cost (a fixed dispatch fee) and the costs for labour, parts, and replacement units. There should be no confusion. This is why it's a good idea to add these fees into the main contract. That way you'll know exactly what you're paying for before you make an emergency call.

8. Competent and qualified Emergency Response Engineers

Emergency engineers need to be among the most highly trained and experienced technicians, not just junior staff working on a rota. They must be able to recognize and fix a wide range of faults in a timely and accurate manner, even under pressure. They should have advanced qualifications for example, the FIA Unit 010(Overhaul Portable Fire Extinguishers), and extensive expertise. Verify whether the service provider employs a team dedicated to emergencies or has specialists that have been vetted.

9. Integration of Alarm Monitoring and Facilities Management Systems

For larger sites or high-risk premises Emergency support must be integrated seamlessly with the existing building management systems. This involves giving direct contact information for alarm receiving centers (ARCs) which allows faults to be identified through automated monitoring and immediately reported to the service provider. Furthermore, the provider should be able to communicate effectively with your in-house facility management team, ensuring the protocols for access to your site and providing updates to the relevant duty manager.

10. Follow-up after an emergency and on compliance Reconciliation in Coventry

The emergency service doesn't end once the engineer departs. The service provider should initiate an official follow-up process to confirm that the incident has been closed within your compliance file. This means the issue of a formal certificate to any equipment that is newly installed or updated in your asset register and requesting to review your Fire Risk Assessment to consider whether the incident could be a sign of the existence of a larger issue (e.g. vandalism that is recurring which requires a measure of control). This closed-loop process ensures that the issue will be addressed not only technically, but administratively as well by restoring the compliance. Have a look at the recommended Coventry fire protection for website recommendations.